Device & Update Management in the PLCnext Ecosystem

Keeping your automation systems up to date can be complex — but it doesn’t have to be. Discover how PLCnext and Proficloud.io simplify secure firmware and software updates through local, cloud, and VPN-based management solutions tailored to your industrial environment.

Why Consistent Device Updates Matter

In industrial applications, regular updates are essential. New firmware versions close security gaps, improve performance, and introduce new features. Without centralized management, however, this entails significant manual effort:

each controller would have to be updated individually — an approach that is hardly practical in complex production environments.

Device and Update Management within the PLCnext Ecosystem automates this process, ensures consistency across all devices, and provides transparency throughout the entire update cycle.

Three Complementary Approaches to Updates

| Solution | Description | Application Area |

|---|---|---|

| Local Device and Update Management | Local system for managing and updating multiple devices within a closed network — independent of cloud or internet connection. | Production plants, factory halls, integrators with isolated IT infrastructures. |

| Device Management Service (Cloud) | Cloud-based platform on Proficloud.io for globally distributed or hard-to-access installations. | Operators of international plants or large device fleets. |

| mGuard Secure Cloud (VPN) | VPN-based remote access for targeted maintenance of individual devices — ideal for service and diagnostic purposes. | Machine builders, service providers, commissioning teams. |

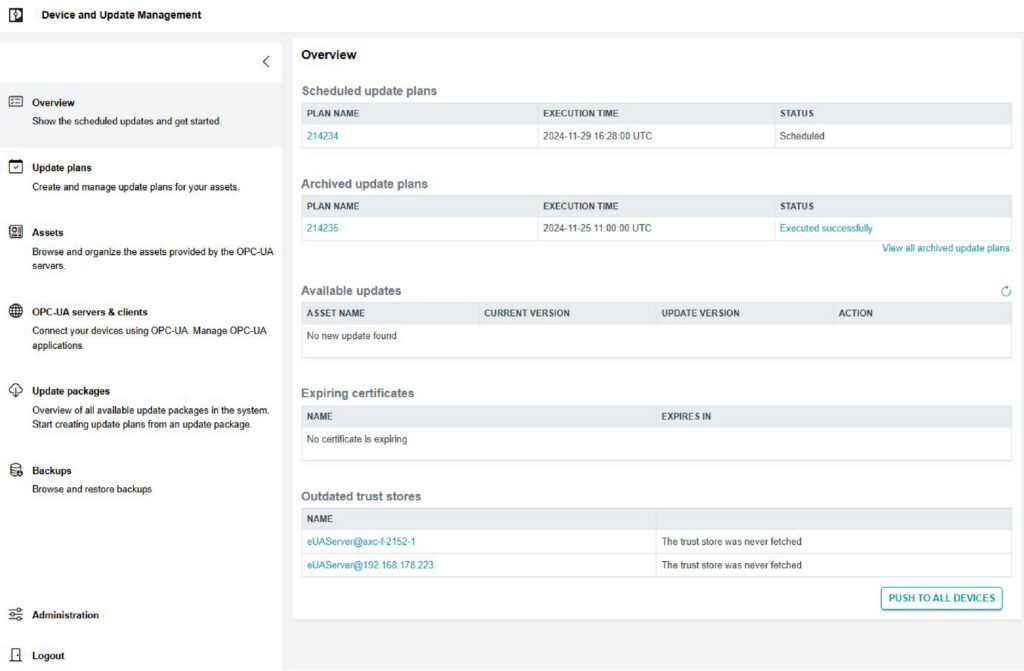

Local Device & Update Management

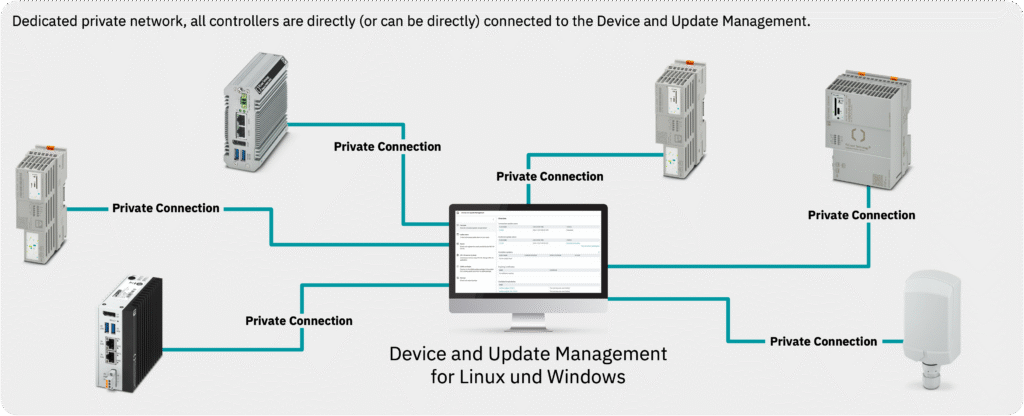

How it works

The local solution enables centralized management of all automation devices — such as controllers, routers, or edge devices — within a closed network.

It is based on OPC UA and supports certificate and role management. Updates can be planned, deployed, and fully documented through defined workflows.

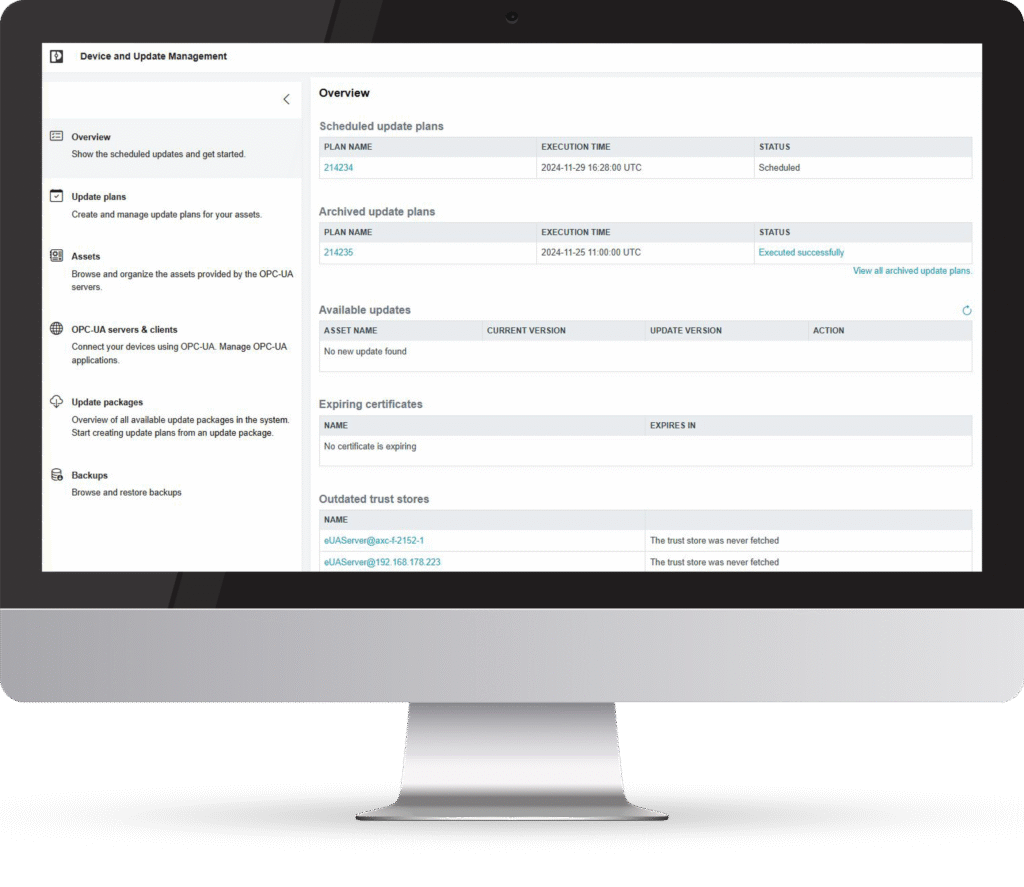

Core features

- Centralized firmware and application updates

- Role and permission management

- Workflow-based update control

- Comprehensive logging and audit trail

Use Case: Automated Updates in Manufacturing

An automotive supplier operates more than 20 injection molding machines with its own controllers. In the past, each controller had to be updated manually — resulting in downtime and significant personnel effort.

With local Device & Update Management, all devices can now be updated in parallel or with a strategy.

Result: Update time reduced from several hours to just a few minutes, no internet access required, full traceability ensured.

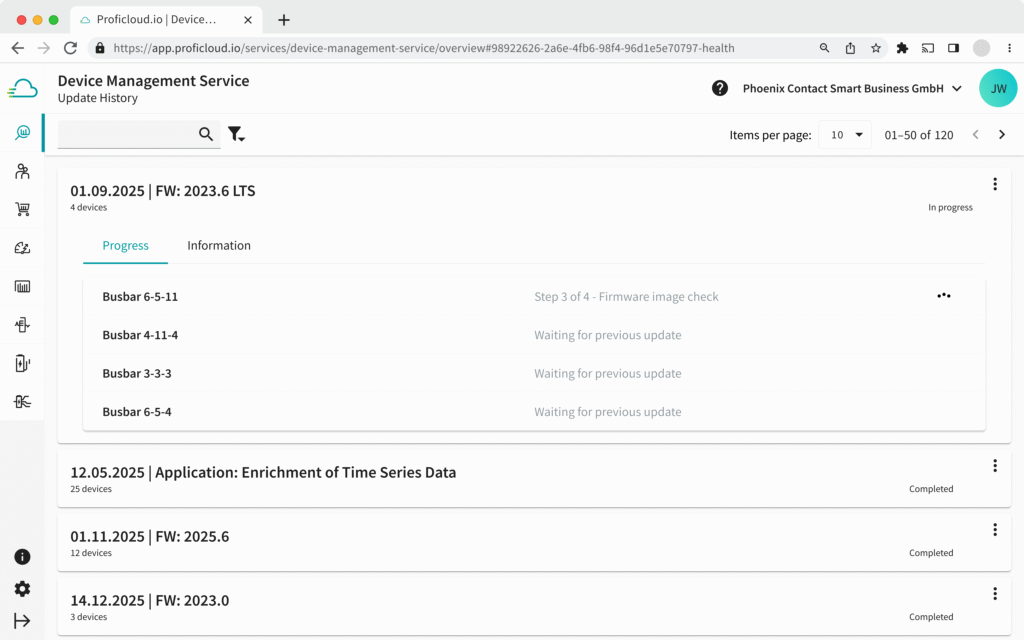

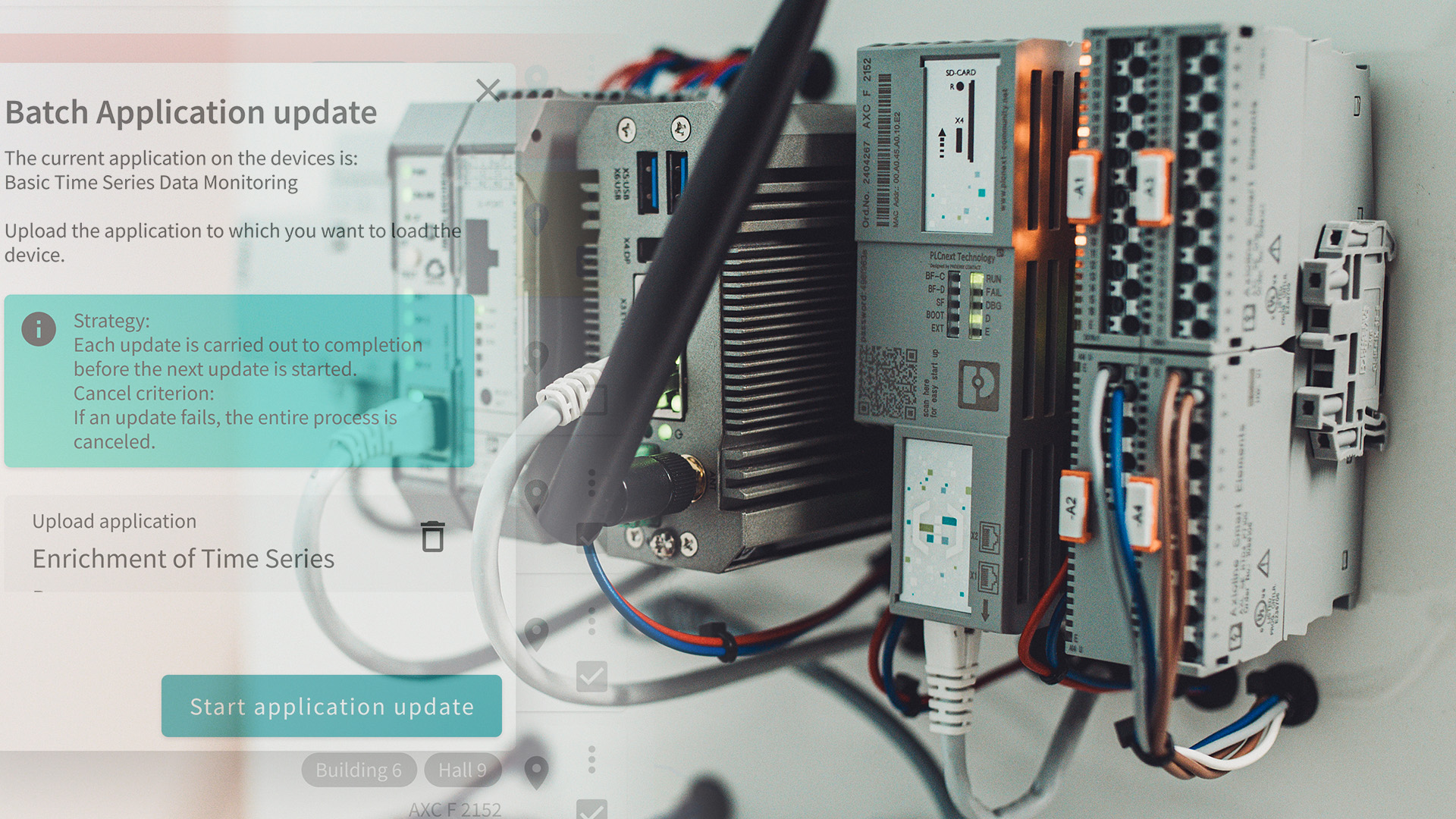

Cloud-Based Device & Update Management

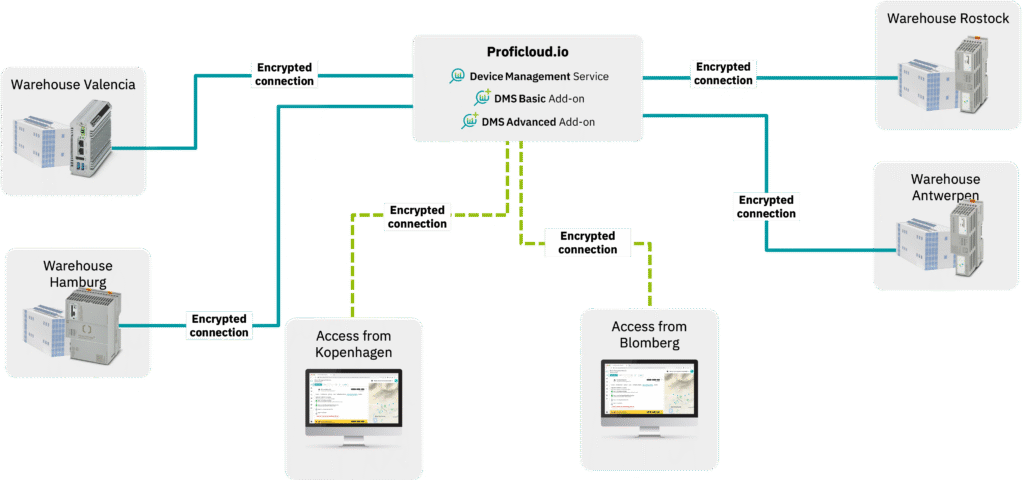

How it works

The Device Management Service on Proficloud.io is the scalable cloud-based solution for distributed or global infrastructures.

It enables centralized access to all registered PLCnext controllers and extends the core functionality through modular add-ons.

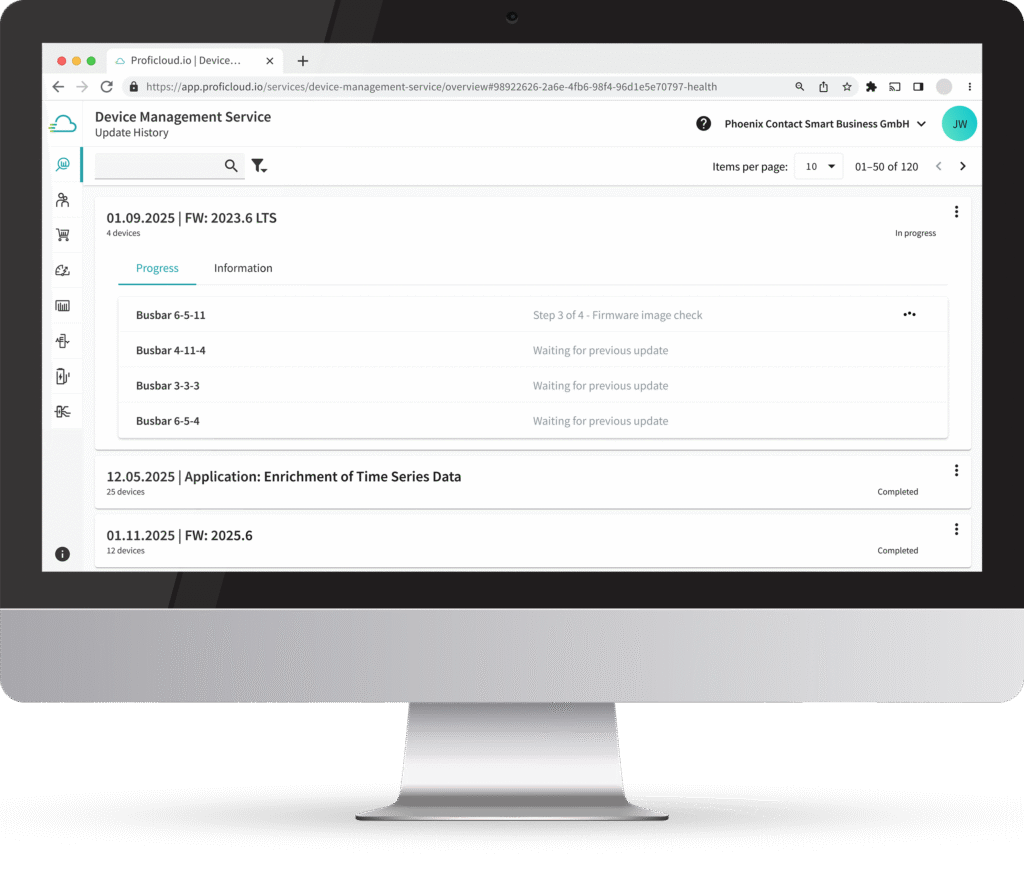

Core features

- Overview of all registered devices (digital nameplate)

- Condition monitoring with alarm functions

- Remote firmware updates directly from the cloud

- Role and permission management

- DMS Basic Add-on: Remote application updates, device grouping, warning notifications

- DMS Advanced Add-on: Batch updates for entire fleets, historical tracking for traceability

Use Case: Centralized Updates for Wind Farms

An operator of several wind farms across Europe must regularly deploy security updates — for example, in response to new regulatory requirements such as the Cyber Resilience Act.

Instead of sending technicians on-site, all installations are managed via the Device Management Service.

Result: Centralized control of all updates, complete documentation, and significant savings in time and cost.

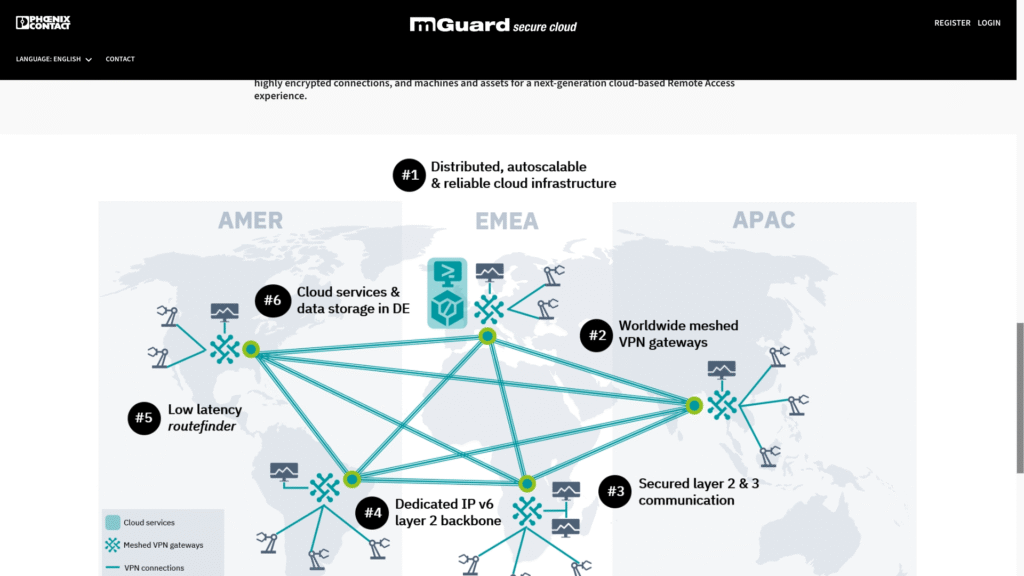

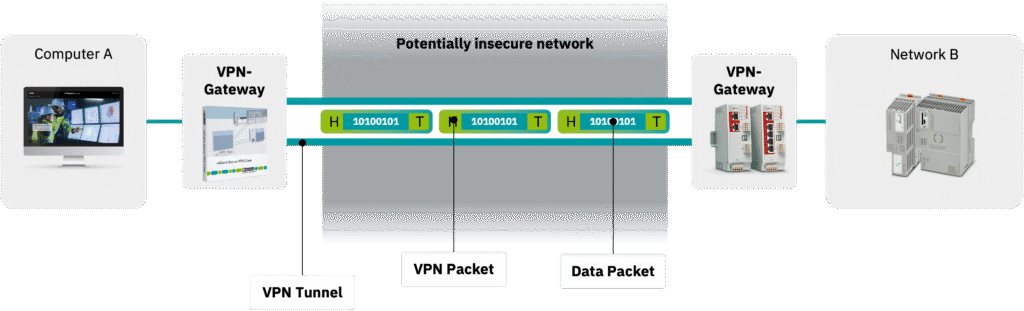

Device & Update Management via VPN (mGuard Secure Cloud)

How it works

The mGuard Secure Cloud provides secure, encrypted VPN access to machines and controllers worldwide.

It is particularly useful when individual devices need to be serviced remotely or issues must be resolved quickly — for example, during commissioning or in service operations.

Core features

- Encrypted IPsec or OpenVPN connections

- Access to controllers, HMIs, and other network participants

- Support for firmware and program updates

- Remote diagnostics, debugging, and configuration

- Free entry-level version (2 connections, 8 GB data volume)

Use Case: Fast Troubleshooting for Global Machines

A machine builder delivers packaging systems worldwide. After commissioning, a customer in the USA reports a malfunction in the control logic.

Instead of sending a service technician, the support team connects directly to the controller via the mGuard Secure Cloud, retrieves log files, and fixes the issue through remote access.

Result: Rapid error analysis, no travel costs, and minimized downtime.

Comparing Local, Cloud, and VPN Solutions

| Feature | Local | Cloud | VPN |

|---|---|---|---|

| Internet Connection | Not required | Required | Temporary, encrypted |

| Objective | Updates and configuration on-site | Centralized management of global fleets | Direct remote access to individual devices |

| Scalability | Plant / factory level | Global | Single devices |

| Transparency / History | Complete | Complete (with add-ons) | Partial |

| IT Effort | Self-managed | Minimized | Minimal |

| Use Cases | Factories, integrators | Operators, OEMs | Service, commissioning |

Within the PLCnext Ecosystem, Phoenix Contact offers the right strategy for every application:

- Local, when security and offline operation are the top priorities.

- Cloud, when large device fleets need to be managed centrally.

- VPN, when targeted remote access is required.

All variants are compatible and can be combined. In this way, Phoenix Contact covers the entire lifecycle of industrial devices — from commissioning to maintenance.

Unified Strategy within the PLCnext Ecosystem

- Updates ensure reliable plant operation and are an essential part of any OT security strategy.

- Phoenix Contact provides scalable tools for this purpose — locally, cloud-based, or VPN-supported.

- These solutions complement each other and enable seamless device management within the PLCnext Ecosystem.

Further information

Get in touch with us.

Together, we will review your infrastructure and show you how all variants can be optimally combined.

We coordinate the local and VPN-based implementations directly with the responsible Phoenix Contact expert teams.

For cloud solutions via Proficloud.io, we provide personal support.