Digital Factory now: The future of production

Discover how Proficloud.io and Digital Factory now work together to transform production with innovative, efficient and sustainable solutions, helping you reach your objectives effectively.

Transforming production with Proficloud.io’s Smart Services and Digital Factory now

In today’s digital world, integrating advanced technologies into production processes is crucial for a company’s success. Proficloud.io and Phoenix Contact’s Digital Factory now work closely together to provide you with innovative solutions that make your production processes more efficient, sustainable and secure. This partnership allows us to offer you tailored solutions that meet your specific needs and help you achieve your goals.

On this page, you will learn how Digital Factory now works, the benefits it offers and how our Smart Services perfectly complement it.

What does Digital Factory now do?

Digital Factory Now offers a variety of solutions along the entire value chain:

- Data Management: Efficient collection, flexible storage and comprehensive analysis of production data.

- Network Integration: Building powerful networks that enable seamless communication between all devices.

- Anomaly Detection: Early detection of deviations to improve product quality and optimize production processes.

- Data Security: Comprehensive security concepts to protect against unauthorized access and ensure compliance with legal requirements.

Benefits of Digital Factory now

Digital Factory now offers numerous benefits that help companies optimize their production processes and increase their competitiveness:

- Increased Productivity: By analyzing and optimizing process data, companies can increase their efficiency and reduce costs.

- Sustainability: Monitoring and analyzing consumption data helps companies reduce their carbon footprint and operate more sustainably.

- Data Security: With comprehensive security concepts, Digital Factory Now protects against unauthorized access and ensures compliance with legal requirements.

Smart Services: Solving production challenges with customized, flexible solutions

Proficloud.io works closely with Digital Factory now to provide our customers with tailored solutions that meet their specific needs. The IIoT-platform proficloud.io and the Smart Services perfectly complement the services of Digital Factory now.

Proficloud.io’s innovative Smart Services offer advanced cloud-based data analysis for deep insights and informed decisions. These flexible and scalable solutions integrate seamlessly into existing infrastructures, enhancing efficiency and addressing production challenges to improve productivity and performance.

- Cloud-based data analysis: Our platform and Smart Services enables in-depth analysis of collected data to gain valuable insights and make informed decisions.

- Scalable solutions: We offer flexible and scalable solutions that seamlessly integrate into existing infrastructure.

- Increased efficiency: By integrating our products, companies can further optimize their production processes and increase their efficiency.

Modular solutions for industrial data collection and automation

Data Collection Box

The Data Collection Box by Phoenix Contact is a compact and modular solution designed for efficient data acquisition in industrial settings. Here are some key hardware features:

- Modular design: The box is designed to be flexible and adaptable, making it suitable for both greenfield and brownfield applications.

- Powerful components: It includes high-performance components that can handle extensive energy and process data collection.

- Local and cloud storage: Data can be stored locally or transmitted to IT or cloud services like Proficloud.io with minimal adjustments.

- Customizable: The hardware can be tailored to specific needs, ensuring it fits various industrial applications.

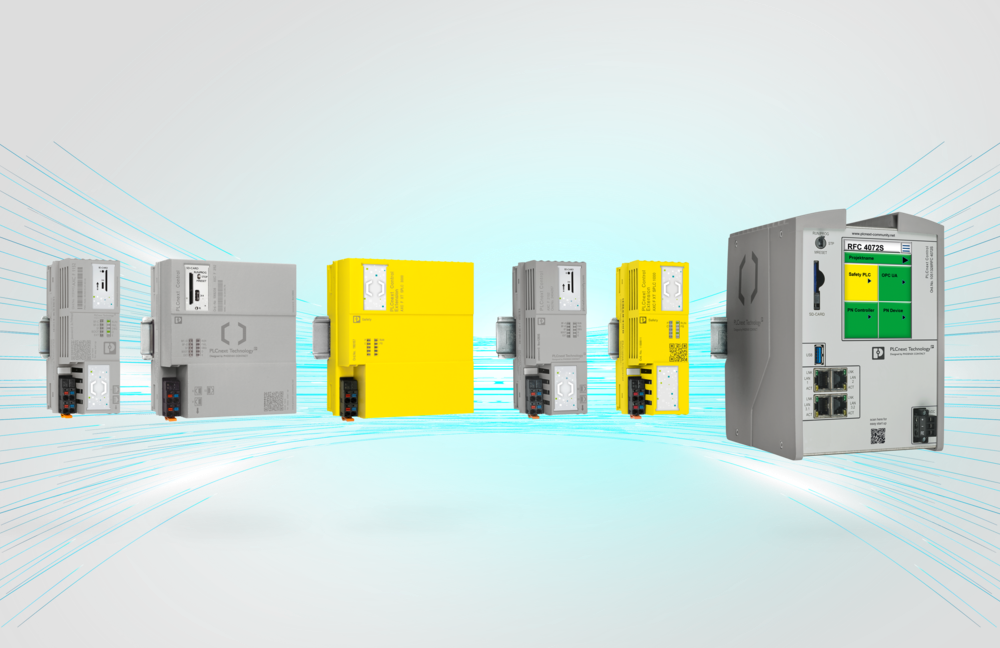

PLCnext Control

PLCnext Control is a robust and versatile hardware platform designed for industrial automation and control systems. It features a modular architecture, allowing for easy expansion and customization to meet specific application needs. Key hardware components include:

- CPU: High-performance processors for complex control tasks, supporting various communication protocols.

- I/O Modules: Interfaces for sensors and actuators, available in digital and analog configurations.

- PSU: Stable power delivery with protection against voltage fluctuations.

- Communication Interfaces: Multiple ports like Ethernet, RS-232 and RS-485 for connectivity.

- Expansion Slots: Allow for additional modules and functionalities.

- Rugged Enclosure: Industrial-grade protection against dust, moisture, and extreme temperatures.

Smart Services

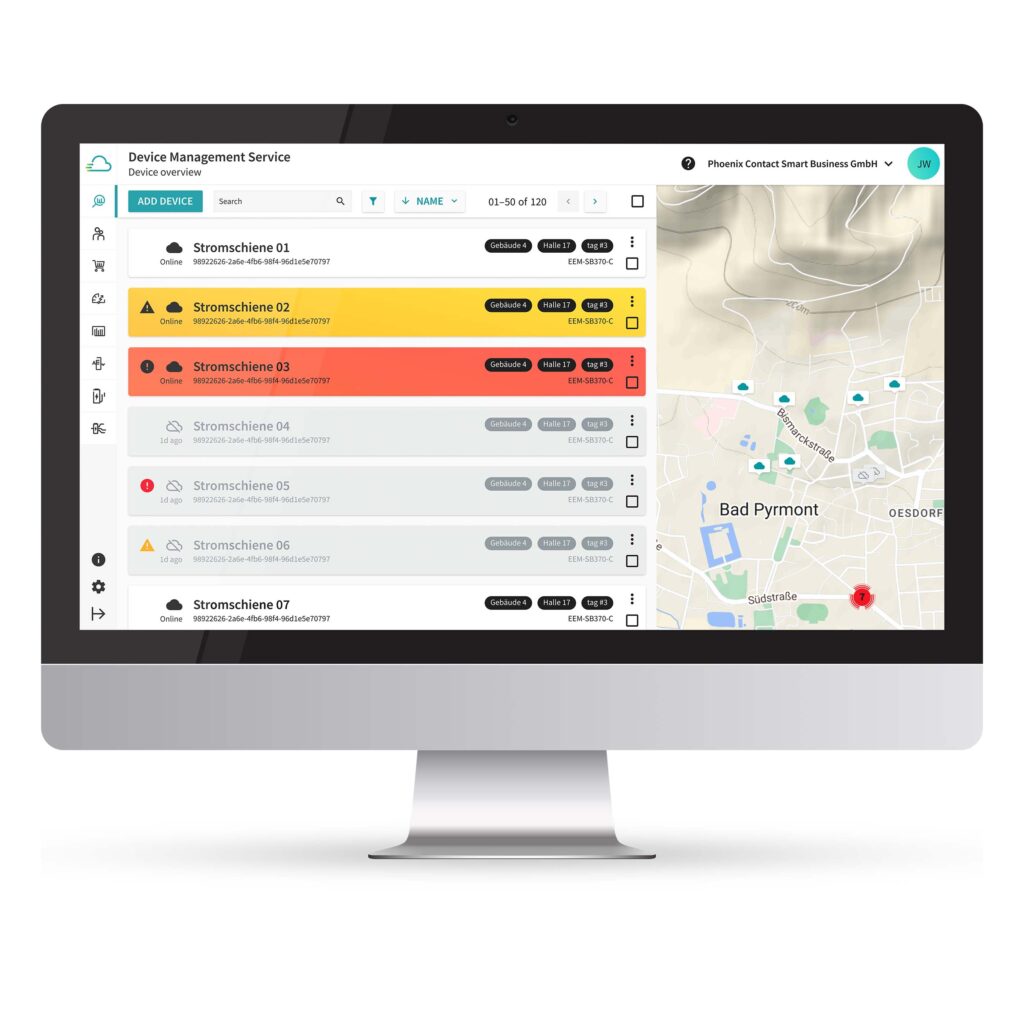

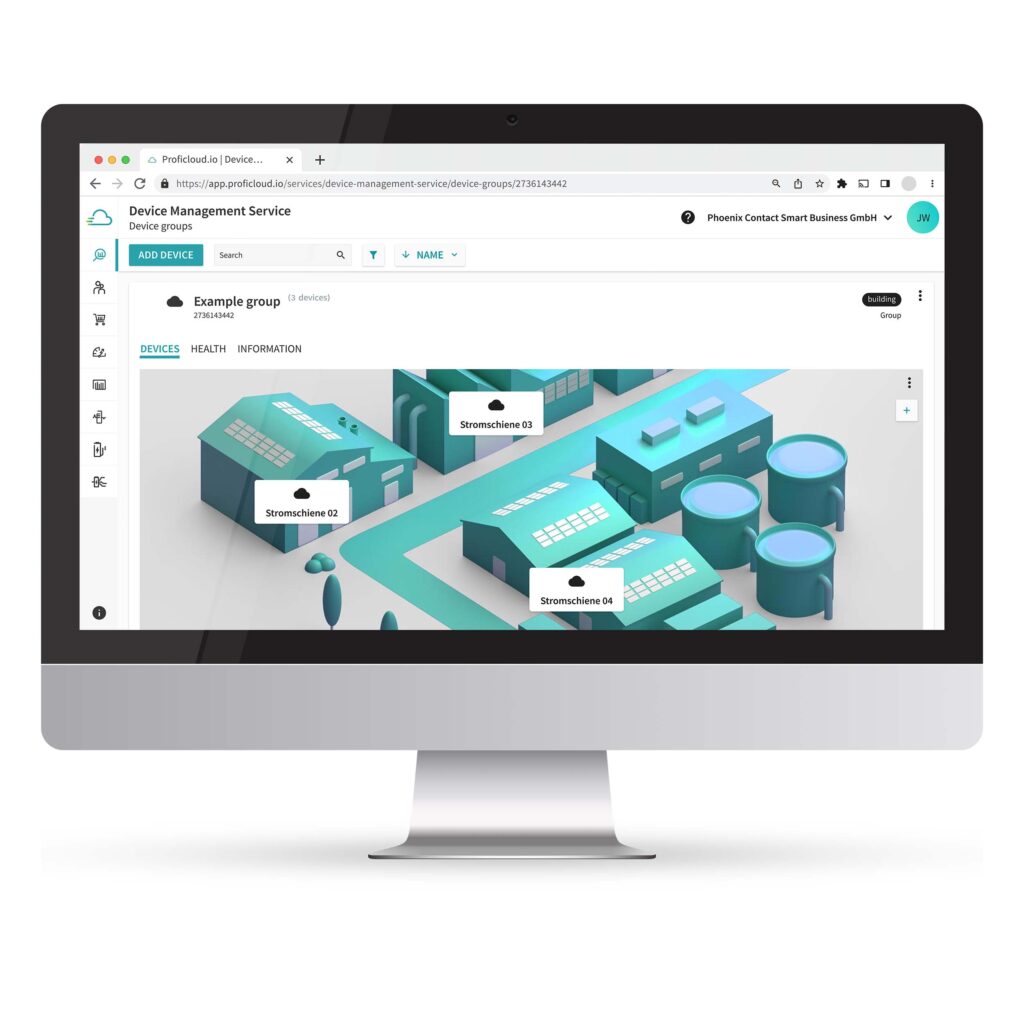

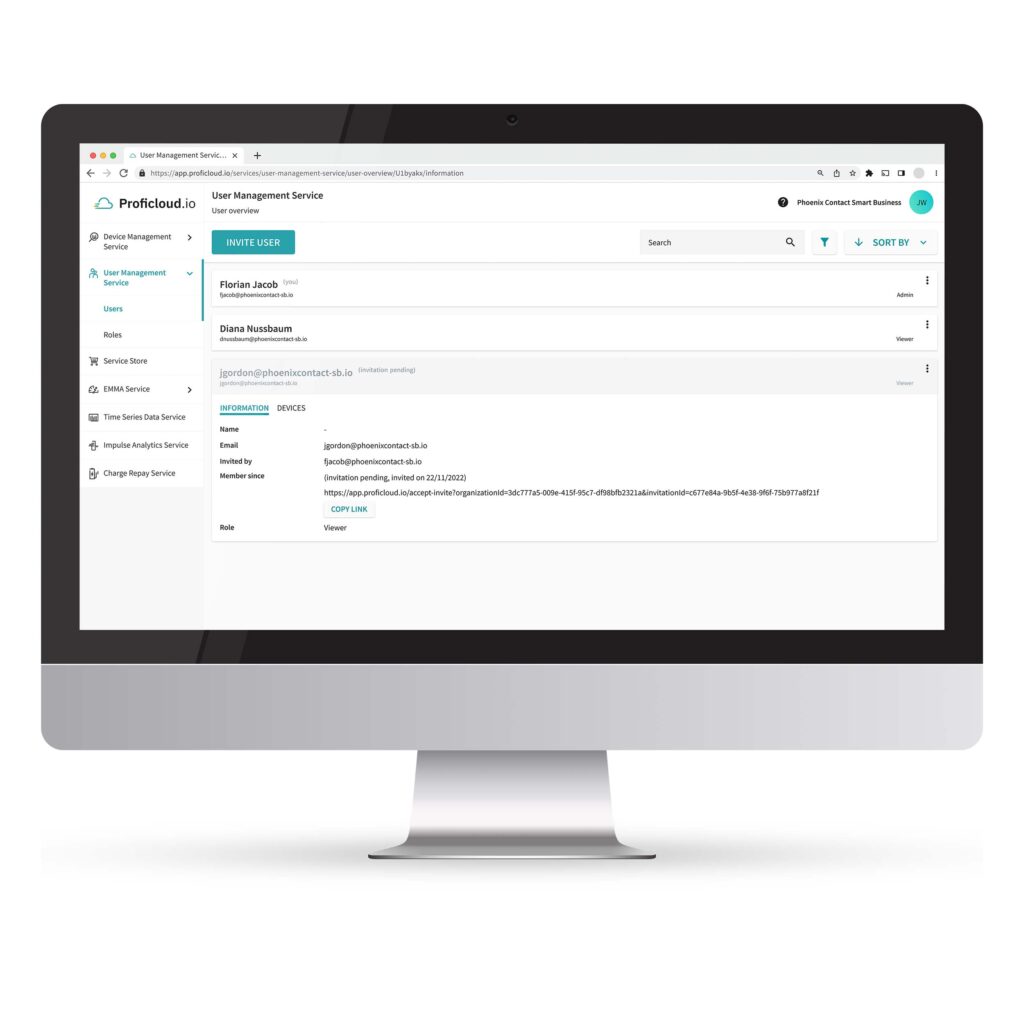

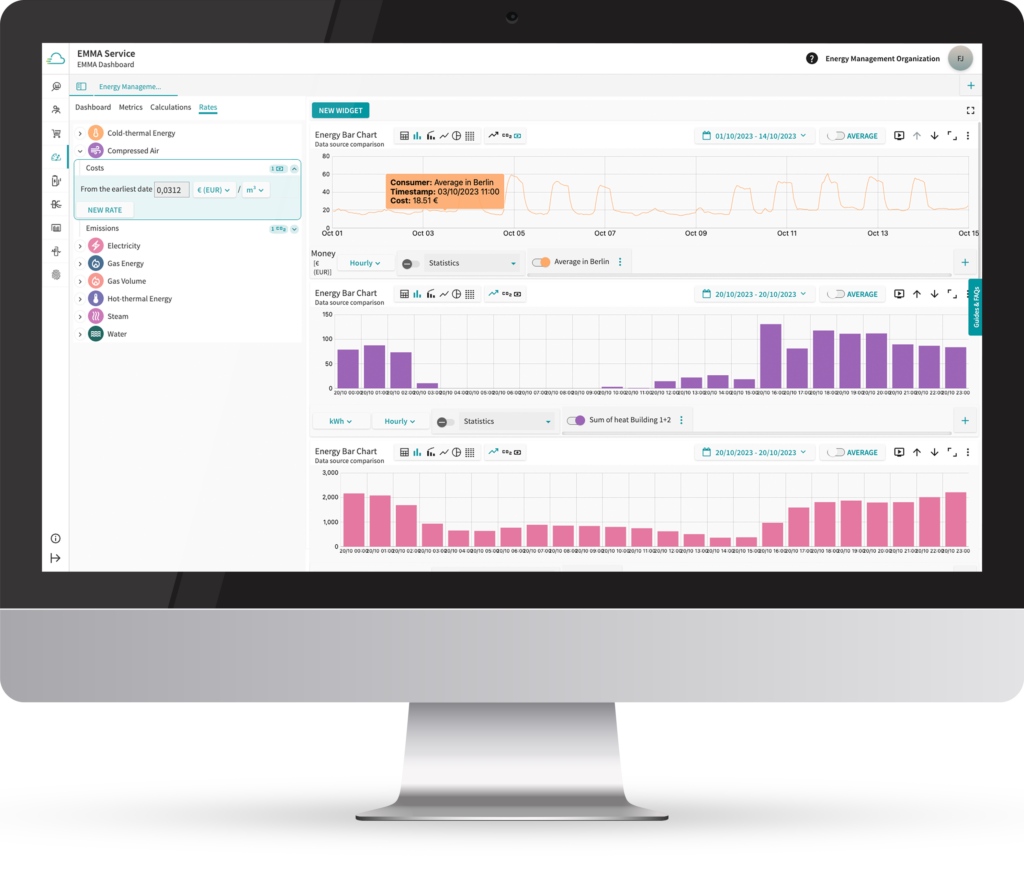

Proficloud.io offers a suite of Smart Services designed to enhance production efficiency and management. The Device Management Service provides real-time monitoring and remote firmware updates, ensuring optimal device performance. The DMS Basic Add-on extends these capabilities with device grouping and health status notifications. The Time Series Data Service allows users to visualize and analyze process data for predictive maintenance and operational optimization. Lastly, the Energy Management Service (formerly EMMA Service) offers tools for monitoring and managing energy consumption, helping users improve efficiency and reduce costs. Each service is tailored to provide users with greater control, insights, and efficiency in their operations.

Products & Smart Services

Why Proficloud.io and Digital Factory now?

The close collaboration between Proficloud.io and Digital Factory now offers numerous advantages:

Enhanced productivity

- Real-time data aggregation and analysis for faster decision-making.

- Transparency and knowledge about all process data for targeted optimization and automation.

Cost reduction

- Elimination of bottlenecks and optimized maintenance work to reduce downtime.

- Efficient production and process chains leading to better cost and margin situations.

Sustainability

- Advanced energy management systems to monitor and optimize energy usage in near real-time.

- Promotion of sustainable production control for a CO₂-neutral footprint.

Data security

- Secure data transfer and storage to protect sensitive industrial data.

- Comprehensive data security measures to safeguard production facilities from cyber threats.

Scalability and flexibility

- Scalable platforms that grow with business needs, allowing easy integration of new devices and services.

- Tailored solutions for different production environments, enhancing operational flexibility.

Ease of use

- User-friendly interfaces and tools that simplify the management and optimization of production processes.

- Designed for businesses with limited IT resources, providing plug-and-play solutions for easy device connectivity.

Solutions for all industries and applications

Further information

Power Reliability – endless possibilities

Discover our solutions for high system availability, consisting of surge protection, power supply, device protection, and energy monitoring.

> More