Connecting PLCnext Control to the Energy Management Service

Discover how PLCnext Technology enables seamless data gathering from various sensors, not just limited to electrical measurements.

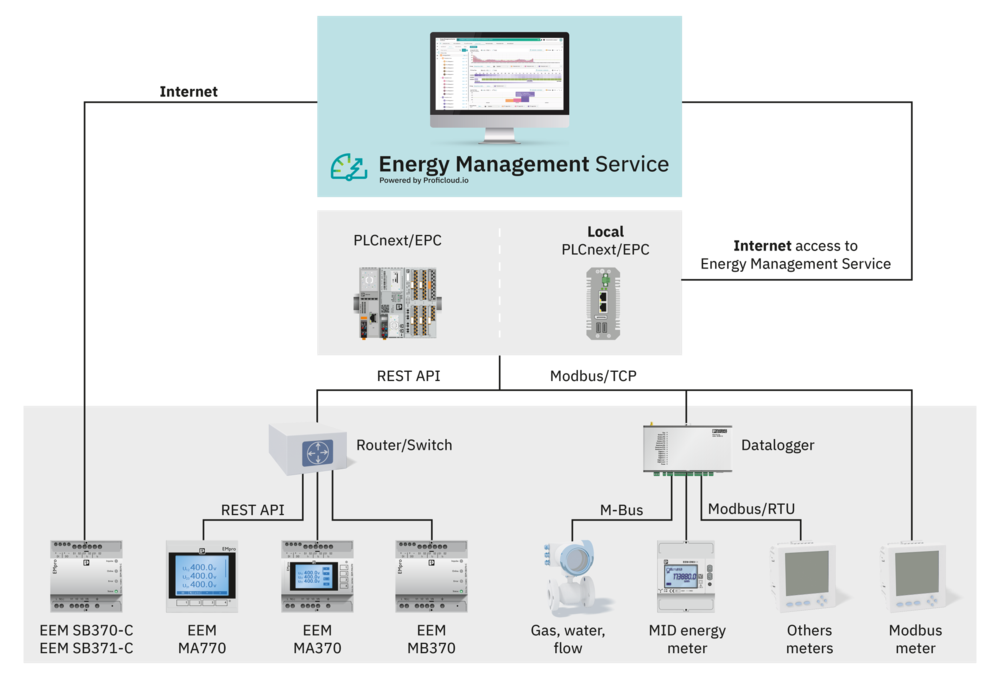

The Energy Management Service support multiple techniques to gather data. The PLCnext Technology provides the possibility to gather and import data from a wide range of sensors and is not limited to electrical energy measurements. Several devices, such as the PLCnext Control AXC F 2152, support connection to Proficloud.io. The cloud variants of the EMpro energy measurement devices (such as the EEM-SB370-C) can be directly connected to Proficloud.io to easily import electrical energy consumption.

In this article, we show how the PLCnext Technology can be used to gather energy data and import it into Energy Management Service, using the AXC F 2152 as an example. A list of other supported controller can be found in the PLCnext Technology Info Center. This setup only requires a supported device, PLCnext Engineer and a Proficloud.io account with an Energy Management Service subscription.

Connecting the Controller to Proficloud.io

To connect a device to the Energy Management Service, the Proficloud.io Service must be configured on the device through the “Web Based Management” (WBM).

First, open the WBM and navigate to Configuration → Proficloud Service. Here, activate the “Proficloud Connection” of the device. Additionally, activate the “Time Series Data” Service to enable data transmission to Proficloud.io, allowing its use in both the Time Series Data Service and Energy Management Service.

The Energy Management Service uses a maximum resolution of 1 minute. Therefore, the “Sampling Interval” and “Publish Interval” can be increased to 60000 ms to save resources. For those planning to use the gathered data in the Time Series Data Service, maintaining smaller intervals might be preferable.

Once the Proficloud.io connection is configured on the device, it can be added to the Proficloud.io Organization.

Copy the device’s UUID from the WBM, or alternatively, find it printed on the device. Navigate to the Device Management Service on the Proficloud.io-Platform and add the device. Shortly after adding, the device should appear online.

Programming the Controller to send data to Proficloud.io

With a successfully established connection to Proficloud.io, the next step is programming the device to send data to the cloud.

Using PLCnext Engineer, setup the project and program the controller as usual. Exporting data to Proficloud.io involves just a few additional steps.

The controller exports any variable to Proficloud.io that fulfills these requirements:

- Marked as “IoT” (in old firmware versions this might be named “Proficloud”)

- Has the Usage “OUT Port”

- Has a “Type” supported by Proficloud.io (see Proficloud.io – Time series data (TSD) connector)

The Energy Management Service does not support boolean values. To use these values within the Energy Management Service, they must first be converted to numerical values.

Importing Data in Energy Management Service

After adjusting the program of the controller the data sent on the Proficloud.io-Platform can be imported into Energy Management Service.

Navigate to the Energy Management Service in Proficloud.io and press the “+” button at the top of the tree view. In the Import Dialog, choose “From Device Management Service.” This will list all compatible devices and their available metrics. Select the desired metrics and specify the units in which these metrics are measured.

Upon pressing the import button, the Energy Management Service will start recording the data provided by the device and the metrics will be added to the Metric Inbox. From there, they can be dragged and dropped into the tree structure to build a digital twin.

Leveraging PLCnext Technology for enhanced data integration

Using PLCnext Technology allow gathering and importing data from a wide range of devices into Proficloud.io and the Energy Management Service. This can enable the usage of existing measurement installations. Additionally, it enables the collection of important metrics besides energy consumptions.