Using Data to Cut Water Use and Stay Compliant at Frigosorno

Turning data into action: how Frigosorno uses IIoT to make smarter decisions about water consumption — while staying ahead of new regulations.

Efficient Utility Metering and Reporting with Smart Servics

How a Chilean Meat Producer Optimizes Resources and Meets New Regulatory Requirements through Digital Monitoring

Favorable climatic conditions such as mild weather, regular rainfall and vast grazing lands allow livestock to be raised under relatively natural conditions in many regions. However, producing high-quality meat still requires significant amounts of water and energy, for example for irrigating fields or during complex cooling processes.

This traditional craft is deeply rooted in the country’s identity and is now at a turning point.

Transparency as the Foundation for Sustainability

Companies that export to international markets are increasingly confronted with stricter requirements regarding animal welfare, resource conservation and consumption transparency. Reducing one’s ecological footprint requires more than good intentions; it demands a clear strategy and the right tools.

Frigosorno, a Chilean meat producer, demonstrates how this can be implemented in day-to-day operations.

- Objective: Reduce greenhouse gas emissions and provide detailed reports on water consumption and treatment to the Chilean government.

- Challenge: A legacy infrastructure developed over more than 70 years, featuring heterogeneous systems.

- Solution: Data acquisition using Data Collection Boxes and analysis with Smart Services.

Frigosorno aimed to gain a precise overview of when and where electricity and water are consumed within the company, not only to increase transparency regarding actual energy and resource usage but also to optimize production processes, identify savings potential and implement efficiency measures.

New Legal Requirements from 2025

Starting in 2025, new legal regulations will require companies to provide a detailed breakdown of water sources, specifying how much is drawn from groundwater and how much comes from alternative sources such as water recycling systems. This necessitates various measurement points and sensors capable of reliably capturing and documenting both the quantity and quality of water used.

Heterogeneous Infrastructure as a Challenge

One of the main challenges of the project launched in 2022 was the existing infrastructure. Frigosorno’s facilities use components from various manufacturers. Some measuring instruments were incompatible with each other, resulting in inconsistent data. This interface issue posed a significant hurdle for many providers since most solutions required replacing existing devices.

The compact unit for capturing water and energy data combines control technology, sensors and networking components. It can be retrofitted into existing systems during ongoing operations, an essential building block for Frigosorno’s digital transformation.

Modular System with Minimal Integration Effort

To digitize Frigosorno’s production, both hardware components and the cloud solution from Phoenix Contact were deployed. In collaboration with a local integrator, several Data Collection Boxes, compact units for capturing and transmitting consumption data, were installed.

Each box includes a PLCnext Controller, energy meters, flow sensors and network components that transmit the collected data to the cloud platform. A key advantage is that many measuring devices can be retrofitted during ongoing operations, minimizing downtime.

Cloud Platform as the Backbone of Data Analysis

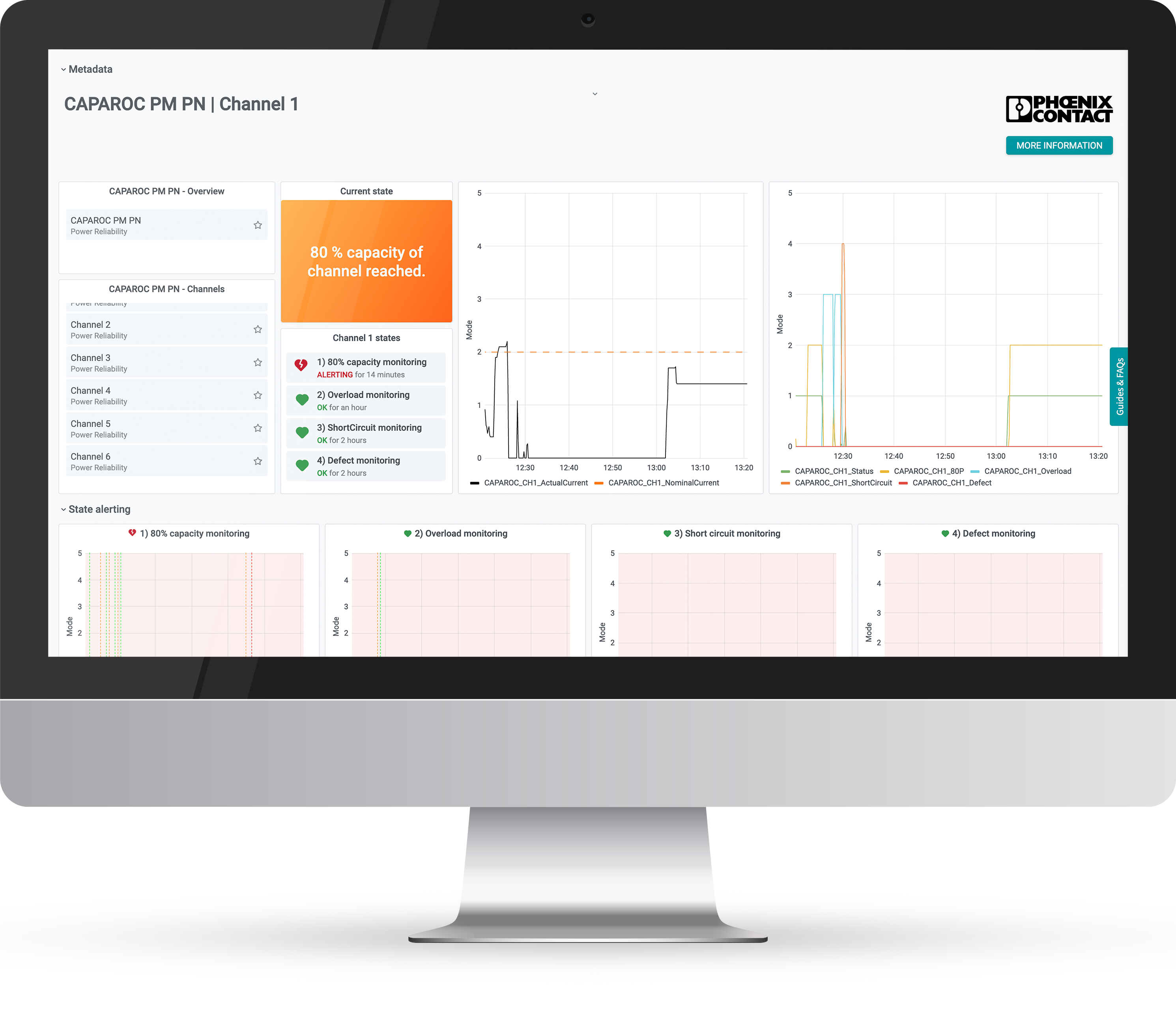

Frigosorno uses the Proficloud.io platform and Smart Services as the central elements for data acquisition and visualization. All data is securely transmitted via MQTT and displayed clearly in the Time Series Data Service.

Both the Data Collection Box and the cloud solution are largely vendor-independent, allowing integration of existing third-party measuring devices. This open architecture makes the system modular, enabling a small-scale start with the option to expand step by step.

Once the controllers are programmed and registered on Proficloud.io, the data can be processed within the Smart Services.

Secure Connectivity—from Field to Dashboard

Previously, Frigosorno exchanged measurement data and control protocols via a standard 4G internet connection. With Proficloud.io, a more secure and user-friendly solution was implemented, one that meets the highest cybersecurity standards. Thanks to the mGuard Secure Cloud connection between systems and servers, all data is reliably protected against cyberattacks at all times.

Frigosorno benefits from a scalable solution. The cloud platform is easy to use, requires low initial investment and does not demand specialized IT expertise. This significantly shortens the time from concept to first data analysis, and a proof of concept can quickly go live.

More Than Consumption Data: Holistic Monitoring

Frigosorno uses graphical evaluations in near real-time to monitor water usage, flow rates and energy metrics. The Smart Service on Proficloud.io visualizes daily, weekly and historical consumption data, clearly structured, scalable and browser-based.

The Smart Service dashboards provide detailed insights into energy and water consumption, an essential prerequisite for evaluating measures to reduce greenhouse gas emissions.

However, reliable monitoring of production processes requires more than just consumption data. Parameters such as grid frequency, load and voltage are also included in the analysis. If anomalies are detected, the integrated alert system can trigger notifications, for example in the case of critical deviations or unusual peaks.

Energy consumption and analytics are clearly displayed in a customized dashboard within the Time Series Data Service, tailored to Frigosorno’s specific needs.

Through digital data acquisition and analysis, Frigosorno not only ensures transparency in resource consumption but also promotes sustainable machine utilization. Predictive maintenance and demand-driven actions can be implemented more effectively, saving energy and reducing operating costs.

A Scalable Path Toward Digital Transformation

By digitizing individual production areas, Frigosorno ensures its competitiveness, operates sustainably and is well-prepared for the future. Thanks to modular components like the Data Collection Box and the cloud platform, monitoring can be flexibly expanded and gradually rolled out across the entire production line. The company is already committed to further digitalization.

What works in Chilean cattle farming can be applied to other industries and regions. The technology itself is agnostic to the values being measured; interpretation and application remain in the hands of the companies.

Frigosorno is a prime example of how even companies with legacy infrastructure can successfully transition to digital production with manageable effort and tangible benefits.

What used to be a gut feeling is now a curve on the dashboard.

Read the article and more in the latest issue of dei – Prozesstechnik für die Lebensmittelindustrie (03/2025), pages 18–19.

Explore the complete reference now

Further information

Request a demo or connect today!

If you have any questions or are interested in live demos, please do not hesitate to contact us. Just get in touch with us!